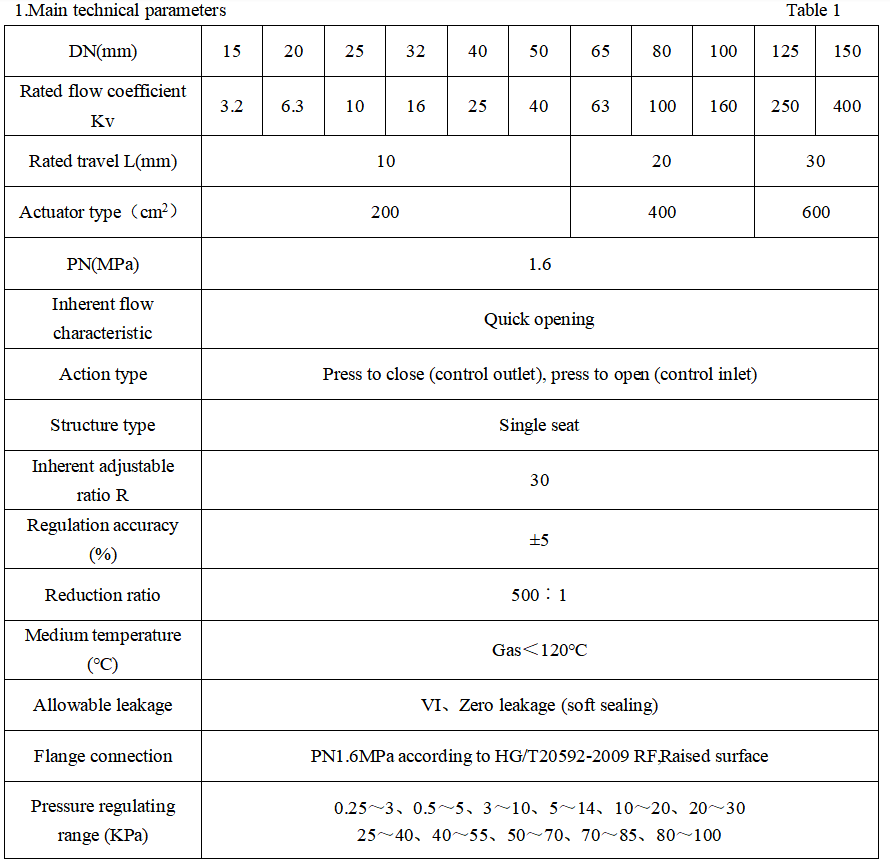

Description

General

ZZYP-16BII Series of Self-operated Pressure Control Valve with Pilot does not need any external power source. It is a product that uses power from adjusted fluid and hence regulates itself automatically. The valve uses a regulating mechanism which has the balanced single-seat valve quick flow characteristic. Internally it uses movable components which have no filter and no friction. It has many characteristics including stable fluid pressure; high adjusting precision; could be used to control micro pressure; safe and reliable sealing performance; and can easily be adjusted on the set value during operation. It is widely used for the micro pressure automatic regulation of all kinds of fuel and half-finished petroleum or automatic adjustment on micro pressure of gas and oil tank storage and gas protection (Nitrogen sealing) tank and heat shielding gas protection occasions.

Characteristic:

1.It’s without any external driving energy, and low equipment cost;

2.Simple structure&small maintenance workload;

3.Pressure set point adjustment is convenient

4.Taking pressure from body,and pipeline installation is convenient;

5.Sensitive control&high control precision

Operational principle:

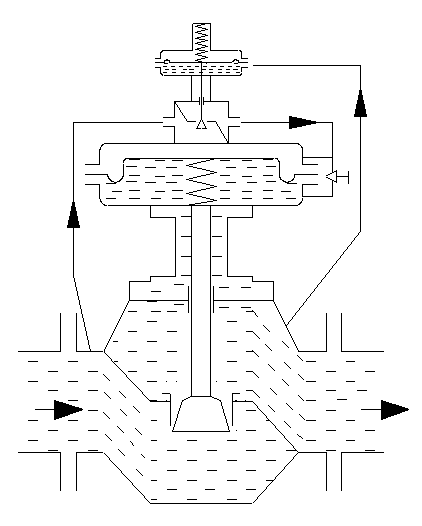

- Operational principle of self-operated outlet pressure control valve with pilot:

The initial plug position is closing, the pilot plug position is opening. When the inlet pressure P1 pass the plug and seat it changes to outlet pressure P2; P1 gets through the pilot and input into the upper and lower diaphragm; use the needle valve control the input gas in the lower diaphragm cover to product pressure difference between upper and lower diaphragm; make the plug of main valve to open; P2 gets through a pressure guiding pipe input lower membrane chamber in the diaphragm; the reaction force and the spring balance spool position determines the opening level of valve and thus controls the outlet pressure.

When the outlet pressure P2 increases, the force P2 acting on the diaphragm also increased. Meanwhile, the force on the diaphragm is bigger than the spring reaction force, which makes the pilot plug close on the seat position and decrease the pilot valve’s opening level; P2 decreased until the force on the diaphragm equals to the spring reaction force and make P2 as set figure and vice versa.

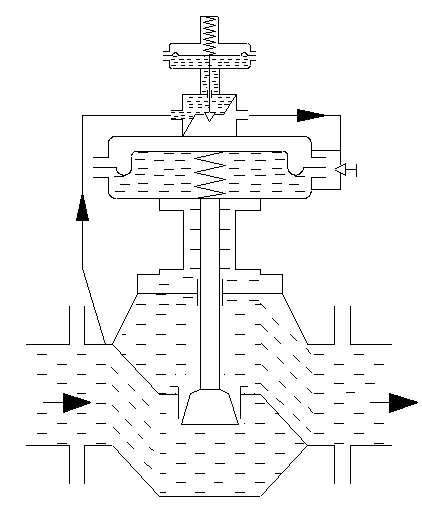

- Operational principle of self-operated inlet pressure control valve with pilot:

The initial plug position is closing, the pilot plug position is closing. When the inlet pressure P1 pass the plug and seat it changes to outlet pressure P2; P1 gets through the director and input into the upper and lower diaphragm; use the needle valve control the input gas in the lower diaphragm cover to product pressure difference between upper and lower diaphragm; make the plug of main valve to open; P1 gets through a pressure guiding pipe input lower membrane chamber in the diaphragm; the reaction force and the spring balance spool position determines the opening level of valve and thus controls the outlet pressure.

When the outlet pressure P1 increases, the force P1 acting on the diaphragm also increased. Meanwhile, the force on the diaphragm is bigger than the spring reaction force, which makes the pilot plug get away from the seat position and increase the pilot valve’s opening level; P1 decreased until the force on the diaphragm equals to the spring reaction force and make P1 as set figure and vice versa.

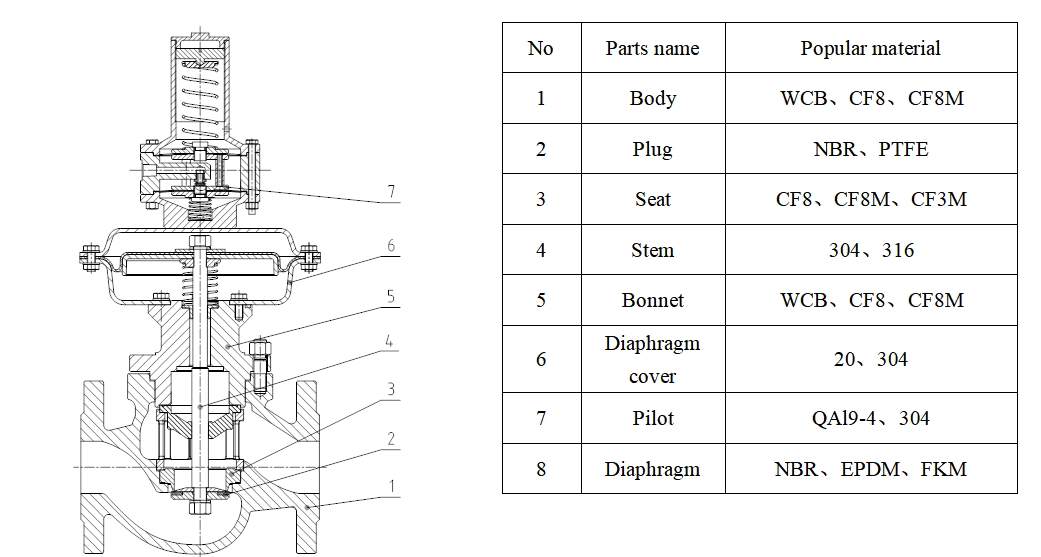

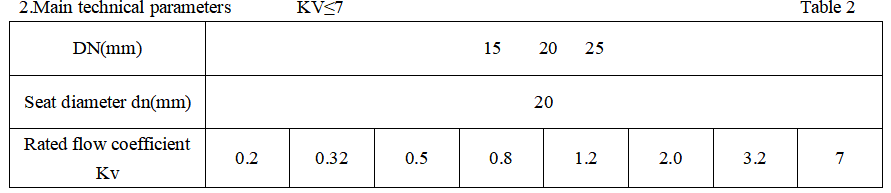

Popular material of main parts

Note:

- Production can be according to customers’ special requirements;

- Flange can be produced according to ANSI、JIS, etc.;

- When the flow is small the diameter stays unchanged; use valve throttling device to achieve customers’ requirements.

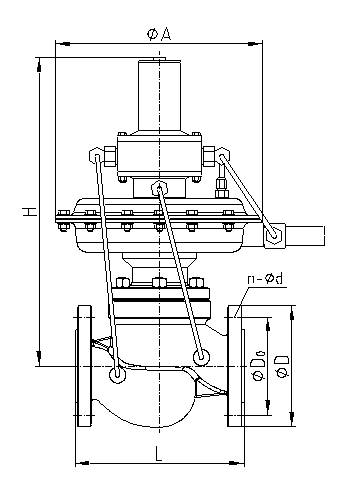

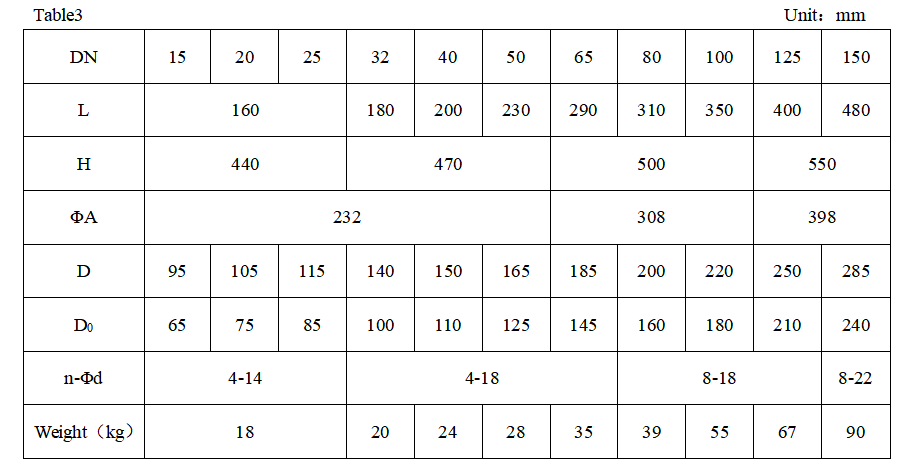

Size and weight

Note:

- Flange standard is HG/T20592-2009 PN1.6MPa;

- Valve body pressure, no external pipeline.

Installation, application and notice

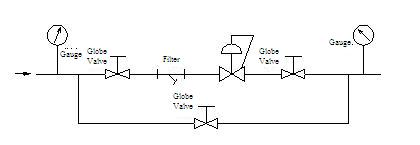

1.Installation:

- Before installation, clean the pipeline to make enough straight pipelines at the entrance and is equipped with filter;

- The valve should be installed vertically upright in horizontal pipelines; inclined when necessary; try to avoid horizontal installation;

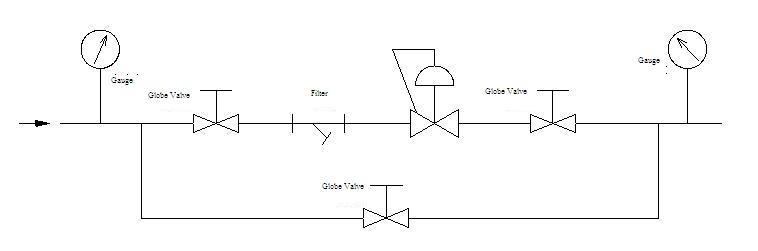

- In order to ensure the product maintenance or faulty continuous production, should be set to bypass valve, as shown below:

Control Outlet Pressure

Control Inlet Pressure

2.Application and notice:

- the outlet pressure is measured to set pressure before delivery. Adjust the nut to change the set pressure.

- The pressure controlling valve should be installed in a place which temperature does not exceed -25~55℃;

- do not arbitrarily adjust the needle valve ;

- it is mainly used for controlling liquid and gas of low and micro pressure, e.g. fuel gas, tank protection gas (nitrogen sealing) and heat treatment gas, etc.