Description

General

ZZY Series of Self-operated Control Valve there is no need for any external power source, only used fluid own energy to adjusted the valve opening automatically, and pressure set value can be adjusted freely during on working condition. With advantages of quick-opening flow characteristic, flexible operation, good sealing performance, stable fluid pressure, high regulating precision level and low leakage etc. it is widely used in automatic control of the inlet-valve and outlet-valve pressure reduction, stabilization of the fluids, such as air, liquid and vapor in various industrial equipments, like industries in petroleum, chemical engineering, electric power, metallurgy, food, light textile, machinery manufacturing and residential buildings, etc. with the condenser, it can continuous on working under 350 degrees steam condition.

Characteristics

1、Without any external driving energy, low cost, Suitable for explosive environment;

2、Simple structure, little maintenance work;

3、The set point can be adjusted and the range is wide, convenient for the user to do continuous adjustment;

4、Body pressure, convenient pipe installation

- Using the pressure balance valve structure, no packing, frictionless movable components, sensitive control, high control precision.

Operational principle

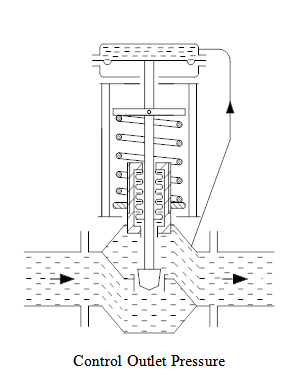

1.Operational principle of self-operated outlet pressure control valve:

The initial plug position is opening. When the inlet pressure P1 pass the plug and seat it changes to outlet pressure P2; P2 gets through a pressure guiding pipe input lower membrane chamber in the diaphragm; the reaction force and the spring balance spool position determines the opening level of valve and thus controls the outlet pressure.

When the outlet pressure P2 increases, the force P2 acting on the diaphragm also increased. Meanwhile, the force on the diaphragm is bigger than the spring reaction force, which makes the plug close on the seat position and decrease the valve opening level; P2 decreased until the force on the diaphragm equals to the spring reaction force and make P2 as set figure and vice versa.

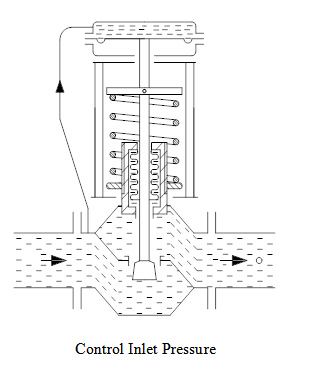

2.Operational principle of self-operated inlet pressure control valve:

The initial plug position is closing. When the inlet pressure P1 pass the plug and seat it changes to outlet pressure P2; P1 gets through a pressure guiding pipe input lower membrane chamber in the diaphragm; the reaction force and the spring balance spool position determines the opening level of valve and thus controls the inlet pressure.

When the inlet pressure P1 increases, the force P1 acting on the diaphragm also increased. Meanwhile, the force on the diaphragm is bigger than the spring reaction force, which makes the plug get away from the seat position and increase the valve opening level; P1 decreased until the force on the diaphragm equals to the spring reaction force and make P1 as set figure and vice versa.

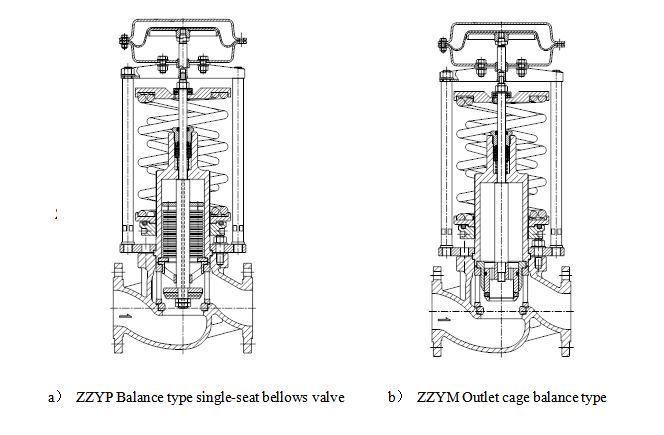

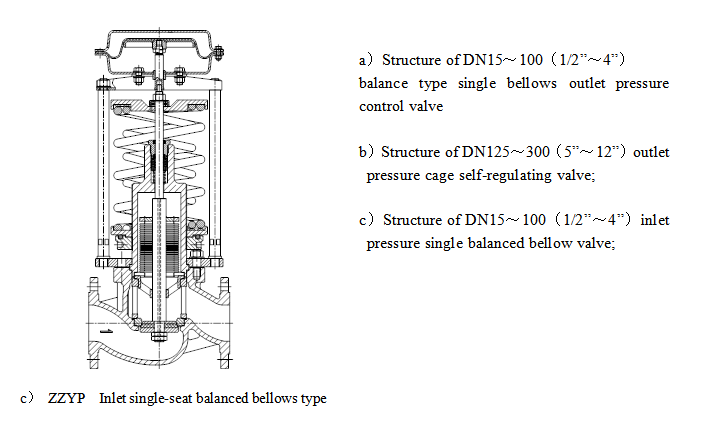

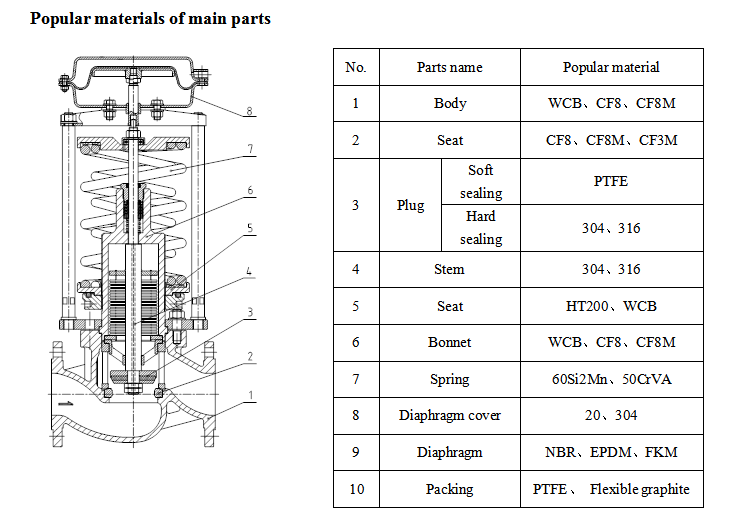

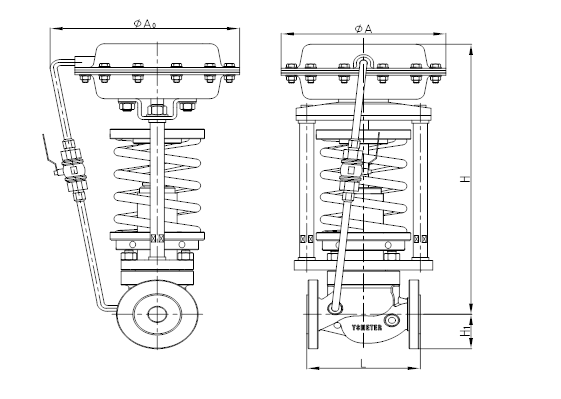

Valve structure

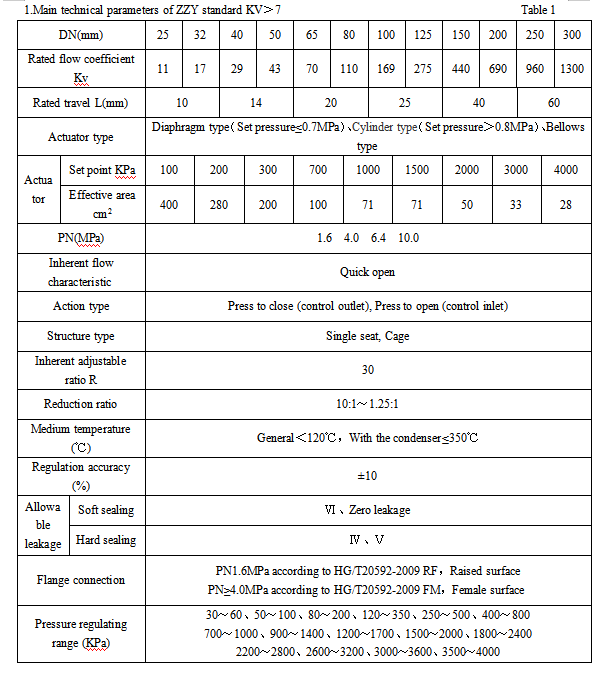

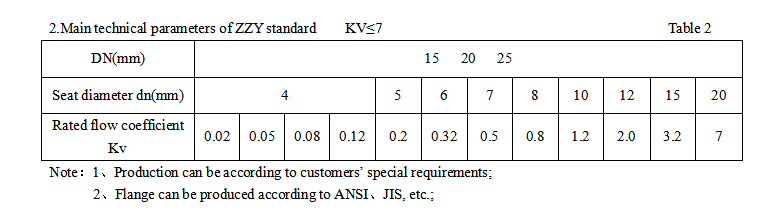

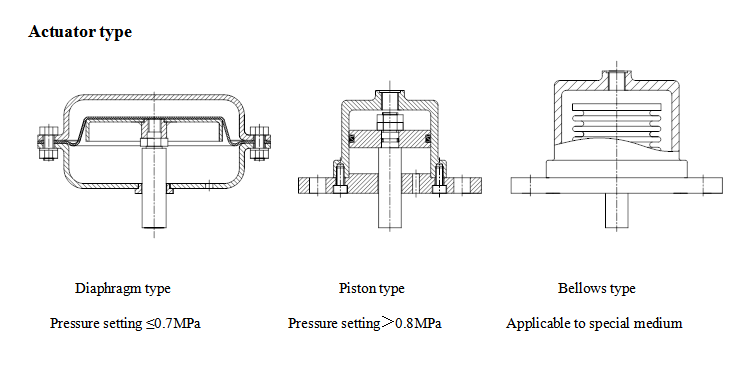

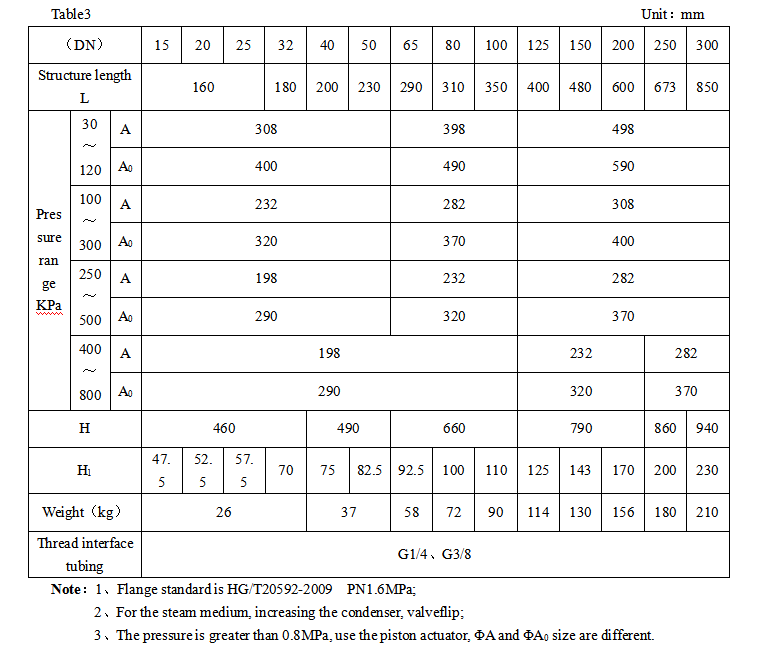

Size and weight

Installation, application and notice

1.Installation:

A Before installation, clean the pipeline to make enough straight pipelines at the entrance and is equipped with filter;

B The valve should be installed vertically upright in horizontal pipelines; inclined when necessary; try to avoid horizontal installation;

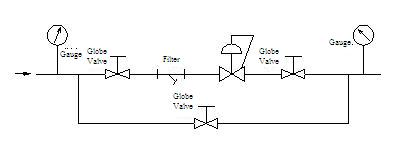

C In order to ensure the product maintenance or faulty continuous production, should be set to bypass valve, as shown below:

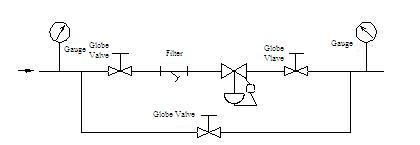

d For the use of the medium for steam, the main valve should flip, condenser shall be located above the adjustable actuator pressure valve and the lower valve pipeline. As shown below:

e When the pressure is too large, such as pressure from 3.5MPa decompression directly to the 0.35MPa, to avoid stopping the use of the valve when the pressure increases lead to the damage of equipment, users are advised to use safety valve or front cut-off.

2.Application and notice

a The outlet pressure is measured to set pressure before delivery. Adjust the adjust plate to change the set pressure.

b When the medium is steam, fill the condenser with water and at the same time open the actuator vent until there is water coming out. Tighten the exhaust gas plug, input water until full, tighten the screw injection nozzle, slowly open the front and back cut-off valves.

Accessories:

1.Tube and taps are equipped with valve;

2.Stainless steel manual ball valve are equipped with valve;

3.Condenser: equipped when the medium is steam.